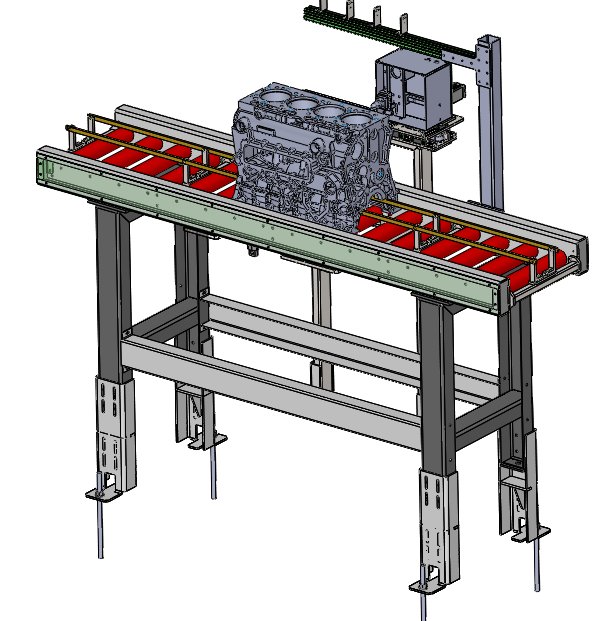

CONVEYOR SYSTEM

The Conveyor System is an important part of the contemporary manufacturing, warehousing and logistics processes, as it is aimed at moving the materials and products at the most efficient way possible with a goal of making the material arrive at the destination. Such systems tremendously minimize the amount of manual work, workflow and guarantee the uninterrupted and automated movement of the materials within the workstations or production lines.

There are many types of conveyor systems: belt conveyors, roller conveyors, chain conveyors, screw conveyors, and overhead conveyors, each of which can be applied in various applications, types of loads, and industries. Small parts to large, heavy-duty material movement conveyors can be designed to fit a particular operational requirement.

Product Description

We construct our conveyor systems to be reliable, fast and

safe. They are configurable in length, width, load capacity and speed

control, which can seamlessly fit in the existing plant layouts.

High-tech models can also have sensors, diverters, indexing, and

communicated with PLC/SCADA controls to sort and route automatically.

Our conveyor systems are a necessity to any industry that wants to run

lean and efficient operations with bottlenecks, an improved throughput,

and minimum handling time regardless of whether you require a simple

conveying system or a fully automated material handling line.

Additional information

- Automated flow of material with less human interference

- Belt, roller, chain, screw and overhead available

- Perfect fit in packaging, assembling, warehousing and logistics

- Adjustable in speed, width, length and load capacity

- Supports integration with sensors, scanners and control systems

- Strong builds, suitable for extreme conditions

- Minimizes downtime, enhances safety and increases productivity

- High uptime with low maintenance

- Appropriate in both light and heavy-duty applications