PLC Programming Services in Pune – Automind Technology

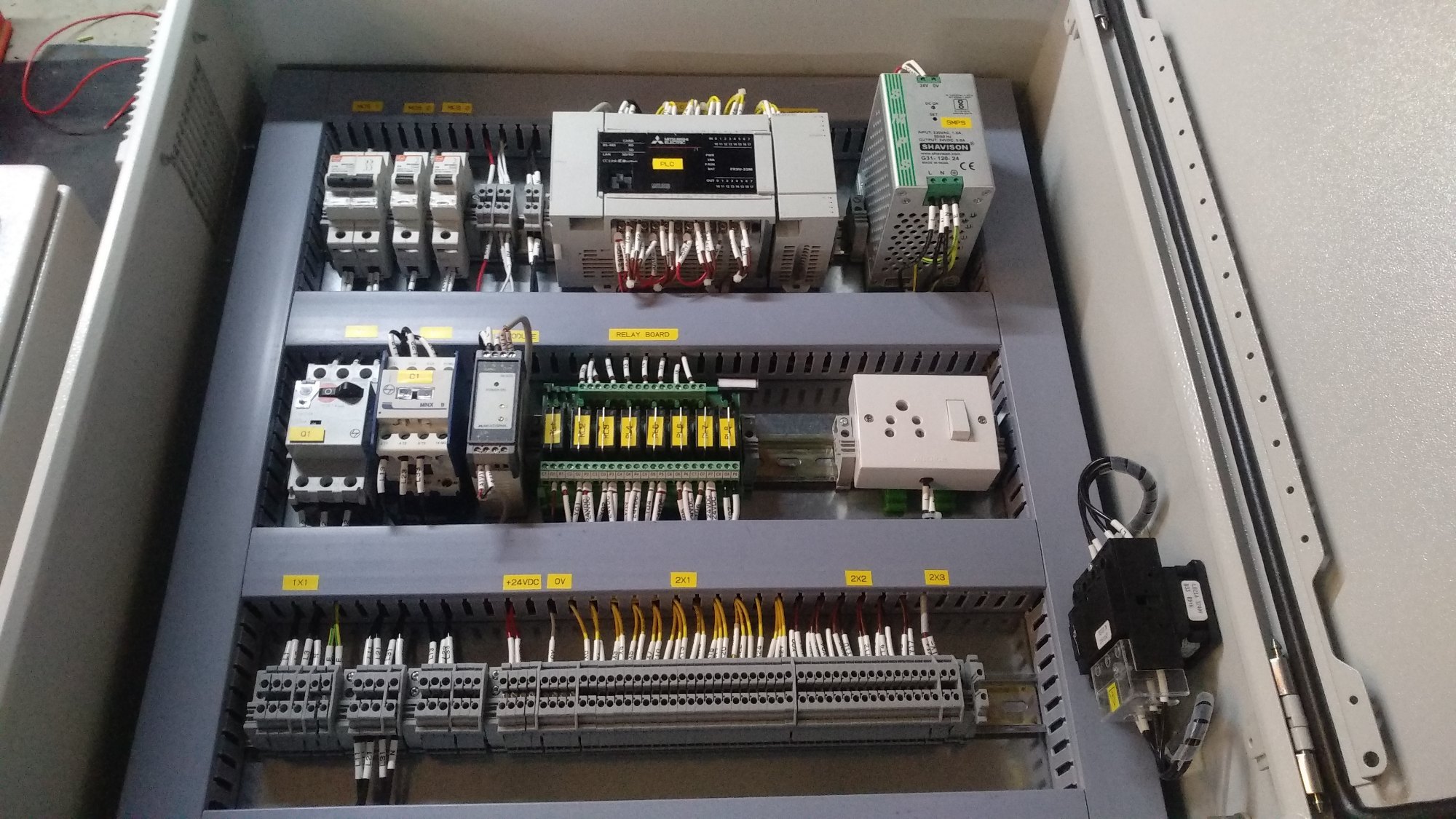

Automind Technology is leading PLC Programming Services in Pune, and Service Providers in Pune. We specialize in applying intelligence to all machines with the help of sophisticated Programmable Logic Controllers (PLC) with brands Siemens, Allen Bradley, Mitsubishi, Delta. We are experts in the design and development of the high-performance logic that is precise, reliable, and scalable to various industrial uses. A brief yet a rich history of excellence, we have already accomplished 1k successful project and 78 or more awards of committed service in the automation industry which has enabled us to become a reliable partner to manufacturing units. This can be supported by the fact that we are officially certified as GST, which guarantees that all of our professional activities comply with the top standards of regulations and industry.

We are leading Programmable Logic Controller Programming Services in Pune

We as PLC programming service providers in Pune do not simply write a code; we create a tailor-made control solution that can fully fit into your working process, enabling you to monitor the process in real time and optimize it. We are service oriented and aim at enhancing productivity of your organization irrespective of the industry sector. Since the selection of the initial material to final process efficiency, we have strict quality control measure to provide low cost and durable automation. Need programming in new installations or in the migration of the old systems, our team offers the necessary delivery in time and will make the systems the most reliable ever.

Types of PLC Programming Services

Being as PLC Programming Service Providers in Pune, according to common technique we provided different types which are given below.

- System Design and Configurement: I/O mapping, processor set up, communication.

- Control Logic Developing: Writing code in languages above auto/manual modes, alarms, sequencing.

- HMI/SCADA Programming: Development of human machine interfaces of monitoring and control.

- Integration Services: Interconnection of PLCs with other systems SCADA, VFDs, robotics.

- Testing & Emulation: Pre-startup testing and validation in PLC Programming Service providers in Pune.

- Support: Troubleshooting, updates, and optimization for PLC Programming Services for Industrial Equipment.

- Specific Solutions: Automation specifically designed to fit particular machines or processes e.g. leak testing, CNC.

Working Process of PLC Programming Services in Pune

| Phase | Activity | Description |

|---|---|---|

| 1. Requirements Gathering | Functional Specification FS | Defining what the machine/process needs to do, including safety protocols, cycle times, and I/O Input/Output requirements. |

| 2. Hardware Selection | Bill of Materials BOM | Selecting the appropriate PLC hardware e.g., Siemens, Rockwell, Schneider, sensors, actuators, and communication modules. |

| 3. Logic Design | Architecture Mapping | Creating flowcharts or state diagrams to map out the sequences, interlocks, and PID loops before writing code. |

| 4. Coding & Development | Programming | Writing the actual code using standard languages like Ladder Logic LD, Structured Text ST, or Function Block Diagrams FBD. |

| 5. HMI/SCADA Integration | Interface Design | Designing the graphical screens that allow operators to monitor and control the PLC system in real-time. |

| 6. Offline Simulation | Virtual Testing | Running the code through simulation software to catch logic errors and "dry run" the process without physical hardware. |

| 7. Commissioning | On-site Implementation | Loading the program onto the physical PLC, wiring checks, and live testing of the machinery under supervised conditions. |

| 8. Optimization & Handover | Fine-tuning | Adjusting timers and setpoints for peak performance. Providing final documentation and training the client's staff. |

Benefits of PLC Programming Services

We as PLC Programming Service providers in Pune, we provided different benefits which are given below.

- Improved Process Effectiveness: Manual operations are automated making them easier to perform and best, saving much time in operations. This directly results in an increment on the day-to-day production output and the overall profitability of the business.

- Higher Accuracy and Precision: PLC logic performs complex computations and analog signals at a high level of accuracy and precision. PLC Automation Services will do away with human factor, and all products will be of precise quality demand.

- Less Operational Downtime: Modular PLCs are tough and are engineered to work in severe environments, and they possess less points of failure as compared to manual systems.

- Flexibility and Scalability: With programming, machine logic can be readily reconfigured with software and still physical wiring is not necessary. This renders it easy to conform to new production needs or change in industry.

- Real-time Monitoring and Safety: Built-in systems offer real-time data visibility and have safety backup to avoid accidents. The full floor of the plant can be monitored with the help of intuitive HMI and SCADA interfaces.

PLC Programming Services in Pune

PLC Programming Services

PLC Programming Services

Applications of PLC Programming Services

We serve as PLC Programming Services in Pune, it is applicable in different sites which are given below.

- Automotive Assembly Lines: We use PLCs to control the conveyor belts and the robots to do the welding and assembly. This guarantees high-speed synchronized flow of production in the manufacture of vehicles.

- Food and Beverage Processing: The services regulate temperature, mixing and batching to ensure high standards of quality. Our filling and packaging lines are also automated to provide high volume efficiency.

- Pharmaceutical Production: cleanroom automation and track-and-trace We offer medication manufacturing cleanroom automation and track-and-trace solutions. This will take into account the safety regulations and proper measurement of ingredients.

- Water and Wastewater Treatment: PLC logic is the control used to operate the pump and check the water level in real-time. Delta PLC Services are used to keep the constant pressure and chemically dosed.

- Special Purpose Machines (SPM): We build specialized logic of unique industrial machines that perform specialized unique operations. These are solutions that provide niche manufacturing precision engineering.

Characteristics of PLC Programming Services.

- Ladder Logic and Function Blocks Custom Development of Logic using Ladder Logic and Function Blocks.

- Fluid HMI/SCADA Interaction in Data visualization.

- Onsite and On-line Remote Programming Support.

- Migration of Old Systems to the New PLC Systems.

Why choose Us as PLC Programming Services in Pune?

- Established Experience: More than three years of effective project accomplishments in different industrial fields.

- Certified Quality: Completely compliant service provider with registered GST and industrial certifications.

- One-Stop Solutions: We offer full-service solutions in designing, developing and commissioning the panel.

- Cost-Effective Engineering: Quality automation solutions based on the affordability of the SMEs and large business.

Automind Technology is well-known PLC Programming Services in Pune, and Service Providers in Pune. Let your manufacturing capabilities be suppressed by old and rigid controls. In Technologies, we do not simply offer you a container of wires, we offer you the head of your automation. We introduce the power of computerized precision of control to your every millisecond of operation. Co-operate with the reliable provider of the services in Pune to future-proof your factory, make it efficient and highly productive. Prepare your industry with our PLC programming excellence in the world today. Contact us for more details.

FAQs

We are well versed with all the major brands such as Delta, Siemens, Allen Bradley and Mitsubishi. Our team is trained to support any type of software environment to suit your requirements in hardware.

Yes, we do provide services of migration and the upgrading of the legacy controllers with the modern PLC systems. This enhances the service and performance of your old machinery without necessarily having to undertake a complete hardware upgrade.

We offer commissioning services on-site as well as remote online programming services to help in quick trouble shooting. This makes sure that the logic problems are solved in time to reduce the production downtime.

Hi there! 👋

Fill out the form below to start a conversation with us on WhatsApp.