PLC HMI SCADA Programming Services in Pune

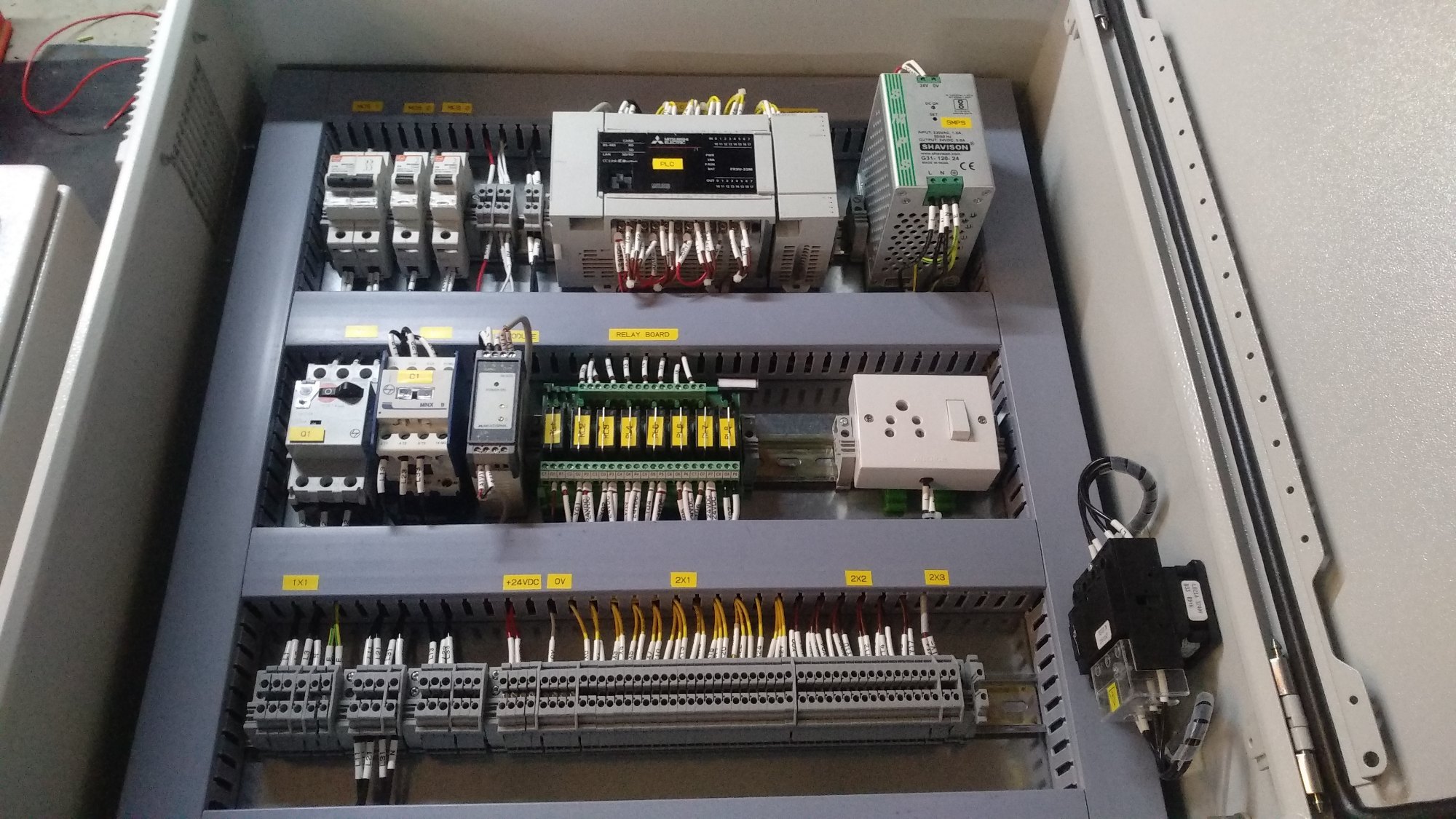

Automind Technology is premier PLC HMI SCADA Programming Services and Service Providers in Pune, Chakan, Bhosari, Baramati, and Ranjangaon. We are experts at digitizing the regular automation. We do not simply write your PLC, HMI and SCADA systems, but we design the central nervous system of your operation. Our programming services also guarantee that your equipment can speak perfectly, your data gives you real time actionable information, and your operators have easy-to-use control interfaces. Stop

controlling downtimes, begin to extract maximum throughput. Through the implementation of engineering intelligence in every machine, we provide scalable, smart and sustainable programs to minimize human error.

Different Brands for Services We Provided:

- Siemens:

- Siemens HMI Programming Service

- Siemens SCADA Programming Service

- Siemens PLC Programming Service

- Allen:

- Allen Bradley HMI Programming Service

- Allen Bradley SCADA Programming Service

- Allen Bradley PLC Programming Service

- Mitsubishi:

- Mitsubishi HMI Programming Service

- Mitsubishi SCADA Programming Service

- Mitsubishi PLC Programming Service

- Delta:

- Delta HMI Programming Service

- Delta SCADA Programming Service

- Delta PLC Programming Service

PLC Programming Services in Pune

PLC Programming Services

PLC Programming Services

What is PLC HMI SCADA Programming Services?

These services include the development of the central software and links as well as the communication of the industrial automation systems:

- PLC (Programmable Logic Controller): HMI Programming Service in Pune is the machine level control logic, which programmes the sequences, timing, and safety interlocks of a particular machine or process.

- HMI (Human-Machine Interface): HMI Programming Service in Pune is the design of the graphical display interface (touch panels or monitors) on which the operators view the status, input commands and respond to alarms.

- SCADA (Supervisory Control and Data Acquisition): SCADA Programming Service in Pune is the plant level monitoring system, which programmes the data gathering, historical trending, alarms and the general supervisory control of one or more machines or all of one facility.

HMI Programming Services in Pune

HMI Programming Services

Maintenance and support of PLC HMI SCADA Programming Services:

Being as recommended PLC HMI SCADA Programming Services in Pune, following is the maintenance process.

- Testing and Simulation: Intensive testing to make sure that the program is operating as expected and to be maintained easily in PLC and SCADA Service Provider Pune.

- Troubled Shooting and On Site Support: On site support of software and hardware issues.

- Annual Maintenance: It is done on routine basis and entails inspection and modification of equipment to ensure that it performs optimally.

- Automation Integration: An integration of many control systems, such as the PLCs, HMIs, SCADA, and other devices, such as servo drives.

SCADA Programming Services in Pune

SCADA Programming Services

Working Principle:

- PLC programming services: Programming of PLC requires engineers to write and debug this control logic. They also do the hardware setup and choosing the appropriate components to a given automation assignment.

- HMI programming services: The HMI programming is the visual interface of a particular machine or process. This involves the development of user-friendly layout, installation of alarm management, and data logging and trending.

- SCADA programming services: The services of SCADA programming include developing the high level program that will combine the information of all the connected PLCs and HMIs. PLC & Robot Programming involves the setting up of data communications protocols, process graphics, data historian and reporting, as well as alarm development.

Interaction of PLC, HMI and SCADA Together:

| Component | Role |

|---|---|

| PLCs (Programmable Logic Controllers) | Allen Bradley PLC HMI SCADA Programming Services serve as the controls on per-machine or per-process logic to execute logic in order to run inputs and outputs. |

| The HMIs (Human-Machine Interfaces) | give an operator a local and on-site perspective of the system where the operator is able to exchange with the machines, look at status (such as pumps and mixers), and carry out operations such as emergency stops. |

| The SCADA (Supervisory Control and Data Acquisition) | systems provide a high-level, bird-eye perspective of the whole operation, which is a synthesis of the multiple PLCs and HMIs to offer supervisory control and in-depth analysis of past trends. |

Benefits of PLC HMI SCADA Programming Services:

As PLC HMI SCADA Programming Service providers in Pune. We provided different benefits which are given below.

- Enhanced Efficiency and Productivity: Automation simplifies work, saves time and improves production.

- Less Human Error: With automated systems, there is reduced error in repetitive tasks that humans are less precise and consistent at on account of human error.

- Process Optimization: Siemens PLC HMI SCADA Programming Services enables real time data to be used to quickly make adjustments towards optimizing processes and increasing performance.

- Cost Savings: Automation may contribute to decreased labour costs and lower operation costs.

- Real-Time Monitoring: SCADA systems can give a centralized image of the processes, which allows operators to monitor the situation and respond to the problems in real-time.

Applications of PLC HMI SCADA Programming Services:

Serve as recommended PLC HMI SCADA Programming Services in Pune, following are the applications as depends on system.

- Energy: The control and monitoring of energy plants and the optimization of the power distribution networks in Mitsubishi PLC HMI SCADA Programming Services.

- Pharmaceuticals: A company in the pharmaceutical industry that is involved in automating and controlling processes to have accurate production and quality.

- Food Beverage: Processes in the food processing industry, managing multiple input/output demands are automated.

- Mining: The mining industry deals with implementation and control of the mining processes.

- Building Management: Managing the heating, ventilation, and air conditioning (HVAC) systems and other processes that are related to the facility in PLC HMI SCADA Programming service providers in Pune.

Why we should be your choice in PLC HMI SCADA Programming Services?

Depending on Delta PLC HMI SCADA Programming Services expertise in state-of-the-art automation, you can select us due to the solutions that are designed to be precise, integrated and scalable to the future:

- Smart Automation Solutions: We will be intelligent enough to mix intelligent automation with smart thinking as PLC HMI SCADA Programming Services in Pune code will be efficient, robust, and progressive.

- Full System Integration: We are offering seamless integration of all three layers (PLC, HMI and SCADA) and are your single knowledgeable control and data system partner

- Real-Time Control and Monitoring: Our systems allow real-time monitoring and control by having well designed control panels whereby the management has a real time view and the responsiveness of the operations.

Automind Technology is outstanding PLC HMI SCADA Programming Services and Service Providers in Pune, Chakan, Bhosari, Baramati and Ranjangoan. do not simply automate things; it provides you with the ultimate, digital power of controlling your whole factory. Demand perfection. Command every data point. Deliver unparalleled uniformity with the coordinated control mechanism that transforms the raw data to market supremacy. Your factory, optimized. Connect us for more details.

Related Searches

PLC Programming Services in Chakan, PLC Programming Services in Bhosari, PLC Programming Services in Ranjangaon, PLC Programming Services in Talegaon, PLC Programming Services in Pimpri-Chinchwad, PLC Programming Services in Shirur, PLC Programming Services in Wagholi, PLC Programming Services in Talwade, PLC Programming Services in Vadgaon, PLC Programming Services in Shirwal, PLC Programming Services in Khed Shivapur, PLC Programming Services in Shikrapur, PLC Programming Services in Pirangut, HMI Programming Services in Chakan, HMI Programming Services in Bhosari, HMI Programming Services in Ranjangaon, HMI Programming Services in Talegaon, HMI Programming Services in Pimpri-Chinchwad, HMI Programming Services in Shirur, HMI Programming Services in Wagholi, HMI Programming Services in Talwade, HMI Programming Services in Vadgaon, HMI Programming Services in Shirwal, HMI Programming Services in Khed Shivapur, HMI Programming Services in Shikrapur, HMI Programming Services in Pirangut, SCADA Programming Services in Chakan, SCADA Programming Services in Bhosari, SCADA Programming Services in Ranjangaon, SCADA Programming Services in Talegaon, SCADA Programming Services in Pimpri-Chinchwad, SCADA Programming Services in Shirur, SCADA Programming Services in Wagholi, SCADA Programming Services in Talwade, SCADA Programming Services in Vadgaon, SCADA Programming Services in Shirwal, SCADA Programming Services in Khed Shivapur, SCADA Programming Services in Shikrapur, SCADA Programming Services in Pirangut.

Frequently Asked Questions (FAQs)

list, control narrative, and preferred hardware/software brand.

Fully commented code, functional specifications, and operator manuals.

We provided different brands like Allen Bradley, Siemens, Delta and Mitsubishi